- If the print has registration mark, click here to see how.

If the print does not have registration mark, click here to see how.

[Printing data with registration mark]

1. Check the following items in both FineCut and RasterLink settings.

1) If printing from FineCut, make sure to click on [Detect Mark] button.

2) If printing from either of FineCut or RasterLink, select [4 points] for search position of

registration marks for higher precision cutting.

3) Check if extra pressure is not applied to the media. If loading roll media, operate

[media feed] function, and pull out the media before cutting, trying to release the

extra pressure.

* See each setting in the [Operation Manual].

2. If the cutting position is misaligned to a certain extent, take the following measure.

* If the cutting position is misaligned irregularly, proper feeding may not be performed

because the media is slippery; thus check the FAQ,

[Q: What if the media is out of position while it is in cutting operation?].

1) Adjust the origin point for cutting in the offset setting.

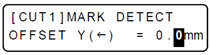

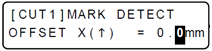

Go to [SETUP] > [MARK DETECT] > [DETECT] > [SIZE] > [OFFSET Y (←)]

> [OFFSET X (↑)]

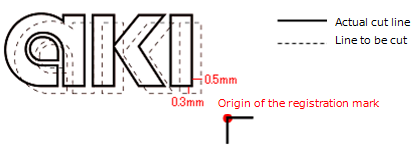

EX) Cutting is performed 0.5mm away to the left and 0.3mm away to the top.

[OFFSET Y: traverse (left and right) adjustment]

Adjust to + direction >> Cutting line slides to the left direction.

Adjust to - direction >> Cutting line slides to the right direction.

The example above shows that the cutting line is 0.5mm off left, thus operate the [▲] [▼] key, and make the setting -0.5mm.

* If it is 0.5mm off right, make it +0.5mm.

[OFFSET X: feeding (front and back) direction adjustment]

Adjust to + direction >> Cutting line slides upper direction.

Adjust to – direction >> Cutting line slides lower direction.

The example above shows that the cutting line is 0.3mm off right, thus operate the [▲] [▼] key, and make the setting -0.3mm.

* If it is 0.3mm off down, make it +0.3mm.

See [Operation Manual] to learn the OFFSET settings.

2) If registration mark is blur, it fails to detect the correct origin, causing fault cutting.

Check up your nozzles and printing conditions to troubleshoot the blur.

3) The color of the media should be white and also, the registration mark should be black. If you

are using the colors other than the mentioned, it may fail to detect the correct position of

registration mark, causing fault cutting.

[Printing data with NO registration mark]

The precision of cutting with registration mark is a lot higher than the one without registration mark.

Especially when you are handling the data 1000mm or longer, we highly recommend for you to perform the print/cutting with registration mark attached. If you are not satisfied with the outcome without registration mark, we urge you to try print/cutting with registration mark.

1. You need to perform [P/C ADJUST] to make the pint and the cutting line match if you are not

marking registration marks.

1) When the print origin and the cutting origin do not match.

2) When the cutting is performed off in the feeding direction:

>>Setup the [P/C SCALE ADJUSTMENT].

(If you are changing the media or feeding stabilization value, it may cause the fault cutting.)

* See the [Operation Manual] to learn [P/C ADJUST] procedure.

2. Slippery media is possible cause for fault feeding. See the following FAQ to troubleshoot

the problem.

[Q: What if the media is out of position while it is in cutting operation?].